Oil Temperature Sender Installation |

|

|

Oil Temperature In all the classes we’ve raced, the oil temperature in the motor is something we wanted to see. Too high an oil temperature is bad for the motor...and too low is bad for performance. What we’re showing here is how we modified the oil pump scavenge manifold to accept a PI, 1/8 NPT oil temperature sender. |

|

|

Modifying the Oil Pump Scavenge Manifold The picture below is of the top of the stock oil pump scavenge manifold. This manifold (which is machined from a piece of billet aluminum) serves to connect the two scavenge stages of the pump together and provide a single output to the oil tank.

Basically, we’re going to drill and tap a hole to the right of -- and on the face perpendicular to -- the scavenge output fitting to insert the temperature sensor.

Start by removing the 4, #10-24 socket head cap screws that hold the scavenge manifold to the oil pump. After you have the 4 screws removed, GENTLY tap the scavenge manifold to loosen the silicon sealant between the manifold and the pump.

Here you see the underside of the scavenge manifold. Note the two inlets into the manifold. They’re sealed to the pump with AS568A-117 O-rings. You can see that if we drill into the scavenge manifold in the right spot, we can sense the oil temperature. The “right spot” is in the middle of the horizontal face of the scavenge manifold and 1" from the right end of the manifold. This location gets the sensor in the oil with minimal impact on flow. Also note that I haven’t cleaned the manifold at this point and you can see the silicone sealer residue. With oiling systems “Cleanliness is next to Godliness”, so at the end of this process, you want to THOROUGHLY clean all parts of the manifold..and you did tape over the open pump outlets, didn’t you?

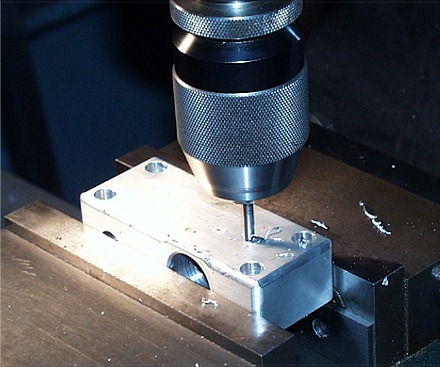

After carefully lining up the location ( in the center of the manifold, 1" from the right side), you want to drill the tap size hole (5/16" for an 1/8" NPT tap).

And now tap and chamfer the hole. When you’re done with the tapping, clean, clean, clean the manifold (I recommend removing the end plug and the output fitting) and make SURE all the shavings are washed out. Put the manifold back together, coat the bottom surface with a thin coat of black silicone sealer and mount the manifold back on the pump.

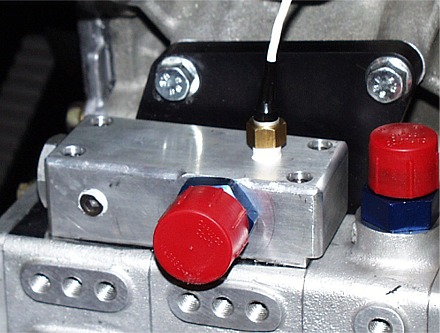

Lastly, here’s the scavenge manifold re-installed on the oil pump with the temp sender in place. Note the plugged hole to the left of the scavenge outlet. I originally put the temp sender there, but it interfered with the alternator. The current location clears everything. One note of caution, don’t over-tighten the mounting screws. I snapped one off during re-assembly.

|

|

| Rev. 3/1/04 | |

| Feedback | |

| I welcome your

comments or ideas on this information. Feel free to drop me a line via

“Comments and Feedback”. Barry Mumm |

|