12/27/01

The pictures below show some of the

changes we've made to the chassis. We've been concentrating on making things

lower and lighter.

Here’s what 45 pounds of sheet metal looks like...after it’s been cut

out of a Cougar. This cutting helped, but we’ve still got about 150

pounds to go.

Interior

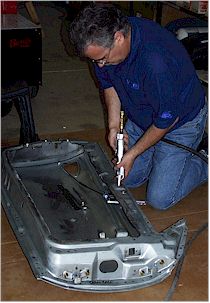

Getting weight out of the car is a big deal...and meeting the rules is equally

important. The rules say you must have a means of opening the door from the

inside. Here Robert is finishing up the installation of the inside door

handles. You can see it next to his left knee...it’s a lever which extends

through the window channel. This solution meets both requirements since we

don’t have any windows left in the doors. Getting weight out of the car is a big deal...and meeting the rules is equally

important. The rules say you must have a means of opening the door from the

inside. Here Robert is finishing up the installation of the inside door

handles. You can see it next to his left knee...it’s a lever which extends

through the window channel. This solution meets both requirements since we

don’t have any windows left in the doors.

To give you a feel for the lightening process. Here’s the inside of a stock

door. To give you a feel for the lightening process. Here’s the inside of a stock

door.

Here’s the same door with only the reinforcement rib left....and 17 pounds

lighter. Here’s the same door with only the reinforcement rib left....and 17 pounds

lighter.

And

in the pursuit of lightweight, here’s the “door” we’re

running. Only a shell. And

in the pursuit of lightweight, here’s the “door” we’re

running. Only a shell.

Next

came fitting of the dashboard. Here you see it with the replacement

gauges and master switch installed. A lot more work than it appears. Next

came fitting of the dashboard. Here you see it with the replacement

gauges and master switch installed. A lot more work than it appears.

So,

with the cage installed, we can now do the final welding and installation

of the pedals and steering. This shot and the one below shows the

development of the pedal mount and steering shaft support. So,

with the cage installed, we can now do the final welding and installation

of the pedals and steering. This shot and the one below shows the

development of the pedal mount and steering shaft support.

After

the welding of the remaining interior components was completed (or so we

thought), we had our friend Denny Marklein (Marklein Auto Body in

Dodgeville, WI) paint the car white.

The white keeps the heat down

inside the car and helps identify any plumbing leaks that might arise. The white keeps the heat down

inside the car and helps identify any plumbing leaks that might arise.

Now we could start mounting components and installing the

plumbing...from brake lines to oil lines. Here you see the Accusump

oil surge tank installed along with the radiator fill tank. Now we could start mounting components and installing the

plumbing...from brake lines to oil lines. Here you see the Accusump

oil surge tank installed along with the radiator fill tank.

Here you see the oil cooler being installed. Note the lightening

holes in the bumper. Here you see the oil cooler being installed. Note the lightening

holes in the bumper.

Chassis Preparation

Here

you see the car as we received it -- a “body in white”.

This is where the work starts Here

you see the car as we received it -- a “body in white”.

This is where the work starts

The

next step was to remove excess material to lower the weight. This

shot shows the area between the “B” and “C” pillars

which had all the metal removed...along with the sound deadening material

that lines the inner panels of the car. The

next step was to remove excess material to lower the weight. This

shot shows the area between the “B” and “C” pillars

which had all the metal removed...along with the sound deadening material

that lines the inner panels of the car.

We then “seam welded” the car -- that

is we added additional welds to all the seams of the car that came from

the factory with spot welds. This increases the rigidity of the

car...but it’s a drag to do. Also in this picture you can see the

stock shock tower before modification. We then “seam welded” the car -- that

is we added additional welds to all the seams of the car that came from

the factory with spot welds. This increases the rigidity of the

car...but it’s a drag to do. Also in this picture you can see the

stock shock tower before modification.

Here’s

the strut tower after modification...with the upper camber plate in

place. Notice we flattened the top of the shock towers to

accommodate a mounting plate. What you can’t see is the

reinforcement plate welded to the underside of the shock

tower. Here’s

the strut tower after modification...with the upper camber plate in

place. Notice we flattened the top of the shock towers to

accommodate a mounting plate. What you can’t see is the

reinforcement plate welded to the underside of the shock

tower.

Fuel Cell

The

next major step was to cut an opening in the car floor to install the fuel

cell. In addition to making this cut, we constructed a steel tube

cage to support and protect the cell. This cage was welded to the

underside of the car and then covered with an aluminum skin. The

next major step was to cut an opening in the car floor to install the fuel

cell. In addition to making this cut, we constructed a steel tube

cage to support and protect the cell. This cage was welded to the

underside of the car and then covered with an aluminum skin.

Here’s

the cell dropped into place prior to building the interior cover which

separates the cell from the cockpit. Here’s

the cell dropped into place prior to building the interior cover which

separates the cell from the cockpit.

Roll Cage

So

after a LOT of cutting and welding, we took the car over to the chassis

builder to get the cage installed. Here’s the car mounted on the

surface plate for construction of the cage. So

after a LOT of cutting and welding, we took the car over to the chassis

builder to get the cage installed. Here’s the car mounted on the

surface plate for construction of the cage.

Here’s

another shot of the car on the surface plate as the cage is being

installed. What follows next are detail shots of the cage. Here’s

another shot of the car on the surface plate as the cage is being

installed. What follows next are detail shots of the cage.

The main hoop of cage. Here you can see the lightened

gussets that connect the cage to the skin of the car. The main hoop of cage. Here you can see the lightened

gussets that connect the cage to the skin of the car.

Here’s the cage thru the passenger side door. Here’s the cage thru the passenger side door.

And here is a shot of the “roof” of the cage. And here is a shot of the “roof” of the cage.

This shot shows the driver's side of the cage with the “NASCAR”

style door bars. This shot shows the driver's side of the cage with the “NASCAR”

style door bars.

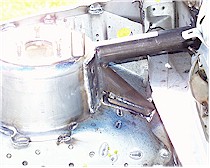

This

is a close-up of the way the cage connects to the rear strut

tower...providing additional safety and rigidity. This

is a close-up of the way the cage connects to the rear strut

tower...providing additional safety and rigidity.

And

here’s the same connection at the front strut tower. And

here’s the same connection at the front strut tower.

Exterior

Here you see the headlight covers, front facia

and oil cooler installed. Note the tow hook on the right.. a nice

aluminum swing away bit made by Robert. Here you see the headlight covers, front facia

and oil cooler installed. Note the tow hook on the right.. a nice

aluminum swing away bit made by Robert.

Here’s

another shot showing the Dzus button mounted facia with the hood closed.

The cardboard is a template for the Lexan replacement of the stock

windshield. Here’s

another shot showing the Dzus button mounted facia with the hood closed.

The cardboard is a template for the Lexan replacement of the stock

windshield.

This

is the front facia with the Wings West air dam mounted on it. We’ve

modified the the air dam to eliminate the lower lip. We replace that

with a custom made splitter/undertray comibnation. This

is the front facia with the Wings West air dam mounted on it. We’ve

modified the the air dam to eliminate the lower lip. We replace that

with a custom made splitter/undertray comibnation.

Here

you can see the mold Robert made to make the splitter/undertray. The

splitter improves the performance of the air dam. The undertray

extends under the car to the centerline of the front axle. We’d go

farther back, but the rules prohibit that. Here

you can see the mold Robert made to make the splitter/undertray. The

splitter improves the performance of the air dam. The undertray

extends under the car to the centerline of the front axle. We’d go

farther back, but the rules prohibit that.

This

shot is looking down at the front of the car. You can see the

lightened stock bumper and the small amount of steel remaining in the

middle of the car. This is the MK2 version...the MK3 will be run in

2002. The short round tubes you see pointing forward, accept the

“legs” of the alignment frame we built. You plug in frames

front and rear and run strings between them...instant reference planes for

doing toe settings. This

shot is looking down at the front of the car. You can see the

lightened stock bumper and the small amount of steel remaining in the

middle of the car. This is the MK2 version...the MK3 will be run in

2002. The short round tubes you see pointing forward, accept the

“legs” of the alignment frame we built. You plug in frames

front and rear and run strings between them...instant reference planes for

doing toe settings.

This

is the bumper we’ll run in 2002. This is a tubular aluminum

structure I built toward the end of the 2001 season but never ran.

It's less than 1/2 the weight of the drilled stock bumper

above. This

is the bumper we’ll run in 2002. This is a tubular aluminum

structure I built toward the end of the 2001 season but never ran.

It's less than 1/2 the weight of the drilled stock bumper

above.

To reduce some weight, we eliminated the stock door handles and covered

the opening with aluminum plate. To reduce some weight, we eliminated the stock door handles and covered

the opening with aluminum plate.

The same goes for the gas filler cap, shown here covered with

aluminum. You can also see the Dzus-buttoned rear facia. The same goes for the gas filler cap, shown here covered with

aluminum. You can also see the Dzus-buttoned rear facia.

This

is the rear wing mount. As you can see it’s adjustable for

angle. The rules for 2002 allow us to mount the wing higher above

the rear deck...which we’ve done. New picture to follow. This

is the rear wing mount. As you can see it’s adjustable for

angle. The rules for 2002 allow us to mount the wing higher above

the rear deck...which we’ve done. New picture to follow.

|