12/10/01

The Kinetics-built Duratec V-6 has really been outstanding. We’ve

had no engine problems and lots of power. Here’s

our air intake system. We’ve put the air filter in the LF headlight

opening. We seal off that area with a combination aluminum

sheet/carbon fiber plate. Here’s

our air intake system. We’ve put the air filter in the LF headlight

opening. We seal off that area with a combination aluminum

sheet/carbon fiber plate.

Archives

.

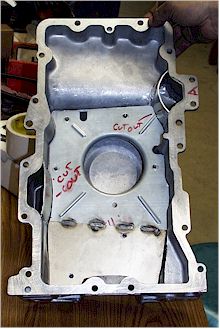

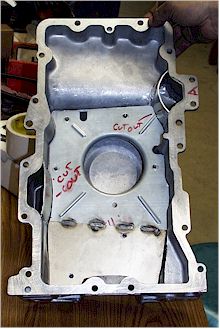

Here’s the oil pan that

was developed for

the dyno. Note the window installed in the side of the pan that allows us to view

what’s happening to the oil while the motor is running. Here’s the oil pan that

was developed for

the dyno. Note the window installed in the side of the pan that allows us to view

what’s happening to the oil while the motor is running.

This shot shows the inside of the developed racing oil

pan. Note the shields on the sides to direct the “drain-back” oil to the

bottom of the pan. Also note the extension of the windage tray to fully cover the

lower part of the oil sump. What you can’t easily see in this photo are the

spots we extended the oil pan to give it more capacity. This shot shows the inside of the developed racing oil

pan. Note the shields on the sides to direct the “drain-back” oil to the

bottom of the pan. Also note the extension of the windage tray to fully cover the

lower part of the oil sump. What you can’t easily see in this photo are the

spots we extended the oil pan to give it more capacity.

This is the motor ready to go into the car,

pre-mounted on the subframe. There are a couple things to note: 1) the solid

aluminum bushings in the subframe -- replacing the stock rubber parts and 2) all the front

suspension and steering is on, ready to go. Someday, we’ll carry a spare motor

and subframe like this ready to install in the car in case of a problem at the track. This is the motor ready to go into the car,

pre-mounted on the subframe. There are a couple things to note: 1) the solid

aluminum bushings in the subframe -- replacing the stock rubber parts and 2) all the front

suspension and steering is on, ready to go. Someday, we’ll carry a spare motor

and subframe like this ready to install in the car in case of a problem at the track.

The motor installed in the car. Note the

solid aluminum motor mount bushings left and right. We originally worried about

vibration with the engine solidly mounted to the chassis. We have found out though,

that there is no vibration issue what-so-ever. Also in this shot, you can see the strut tower brace

installed behind the motor. The motor installed in the car. Note the

solid aluminum motor mount bushings left and right. We originally worried about

vibration with the engine solidly mounted to the chassis. We have found out though,

that there is no vibration issue what-so-ever. Also in this shot, you can see the strut tower brace

installed behind the motor.

This picture is taken from underneath and behind the

motor. You can see here how the stainless steel headers exit from the

subframe. In addition, you can see another aluminum motor mount bushing...again,

soon to be replaced with a tube steel fabrication. This picture is taken from underneath and behind the

motor. You can see here how the stainless steel headers exit from the

subframe. In addition, you can see another aluminum motor mount bushing...again,

soon to be replaced with a tube steel fabrication.

Here's Jim Bacon who helped us with the calibration of

the engine control system. Jim has really been super supportive of

this project. Here's Jim Bacon who helped us with the calibration of

the engine control system. Jim has really been super supportive of

this project.

What follows are some

pictures of the head being developed. A lot of work has gone into these parts. What follows are some

pictures of the head being developed. A lot of work has gone into these parts.

Here’s a look at the first type of header we’re

trying. More experimentation here. Here’s a look at the first type of header we’re

trying. More experimentation here.

The first generation rod and

piston. Some experimentation here too. The first generation rod and

piston. Some experimentation here too.

.

Here’s a picture of the head on

the flow bench. Here’s a picture of the head on

the flow bench.

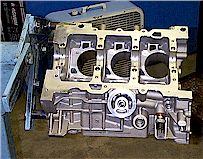

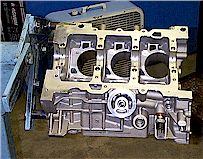

Here’s the block disassembled. Here’s the block disassembled.

|

Here’s

our air intake system. We’ve put the air filter in the LF headlight

opening. We seal off that area with a combination aluminum

sheet/carbon fiber plate.

Here’s

our air intake system. We’ve put the air filter in the LF headlight

opening. We seal off that area with a combination aluminum

sheet/carbon fiber plate. Here’s the oil pan that

was developed for

the dyno. Note the window installed in the side of the pan that allows us to view

what’s happening to the oil while the motor is running.

Here’s the oil pan that

was developed for

the dyno. Note the window installed in the side of the pan that allows us to view

what’s happening to the oil while the motor is running. This shot shows the inside of the developed racing oil

pan. Note the shields on the sides to direct the “drain-back” oil to the

bottom of the pan. Also note the extension of the windage tray to fully cover the

lower part of the oil sump. What you can’t easily see in this photo are the

spots we extended the oil pan to give it more capacity.

This shot shows the inside of the developed racing oil

pan. Note the shields on the sides to direct the “drain-back” oil to the

bottom of the pan. Also note the extension of the windage tray to fully cover the

lower part of the oil sump. What you can’t easily see in this photo are the

spots we extended the oil pan to give it more capacity. This is the motor ready to go into the car,

pre-mounted on the subframe. There are a couple things to note: 1) the solid

aluminum bushings in the subframe -- replacing the stock rubber parts and 2) all the front

suspension and steering is on, ready to go. Someday, we’ll carry a spare motor

and subframe like this ready to install in the car in case of a problem at the track.

This is the motor ready to go into the car,

pre-mounted on the subframe. There are a couple things to note: 1) the solid

aluminum bushings in the subframe -- replacing the stock rubber parts and 2) all the front

suspension and steering is on, ready to go. Someday, we’ll carry a spare motor

and subframe like this ready to install in the car in case of a problem at the track. The motor installed in the car. Note the

solid aluminum motor mount bushings left and right. We originally worried about

vibration with the engine solidly mounted to the chassis. We have found out though,

that there is no vibration issue what-so-ever. Also in this shot, you can see the strut tower brace

installed behind the motor.

The motor installed in the car. Note the

solid aluminum motor mount bushings left and right. We originally worried about

vibration with the engine solidly mounted to the chassis. We have found out though,

that there is no vibration issue what-so-ever. Also in this shot, you can see the strut tower brace

installed behind the motor. This picture is taken from underneath and behind the

motor. You can see here how the stainless steel headers exit from the

subframe. In addition, you can see another aluminum motor mount bushing...again,

soon to be replaced with a tube steel fabrication.

This picture is taken from underneath and behind the

motor. You can see here how the stainless steel headers exit from the

subframe. In addition, you can see another aluminum motor mount bushing...again,

soon to be replaced with a tube steel fabrication. Here's Jim Bacon who helped us with the calibration of

the engine control system. Jim has really been super supportive of

this project.

Here's Jim Bacon who helped us with the calibration of

the engine control system. Jim has really been super supportive of

this project. What follows are some

pictures of the head being developed. A lot of work has gone into these parts.

What follows are some

pictures of the head being developed. A lot of work has gone into these parts.

Here’s a look at the first type of header we’re

trying. More experimentation here.

Here’s a look at the first type of header we’re

trying. More experimentation here. The first generation rod and

piston. Some experimentation here too.

The first generation rod and

piston. Some experimentation here too. Here’s a picture of the head on

the flow bench.

Here’s a picture of the head on

the flow bench. Here’s the block disassembled.

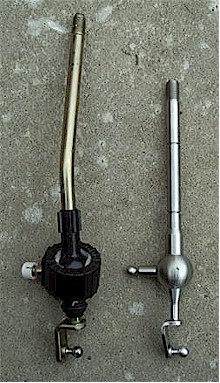

Here’s the block disassembled. This

picture compares the stock shifter (on the left) with the B&M short

throw shifter. We take the B&M shifter and modify it by welding an

AN bolt in place of the lower linkage ball. This allows us to use

spherical rode ends retained with nylock nuts in place of the snap lock

stock system (which can -- and has -- fallen off during a race).

This

picture compares the stock shifter (on the left) with the B&M short

throw shifter. We take the B&M shifter and modify it by welding an

AN bolt in place of the lower linkage ball. This allows us to use

spherical rode ends retained with nylock nuts in place of the snap lock

stock system (which can -- and has -- fallen off during a race). Here

you can see the transmission end of the shift linkage. We modified

the shifter mechanism at the transmission in the same manner...welding

bolts on in place of the snap on fittings.

Here

you can see the transmission end of the shift linkage. We modified

the shifter mechanism at the transmission in the same manner...welding

bolts on in place of the snap on fittings. We

had a problem with the teeth of the gears stripping. We're making

good power and on hard acceleration, the weak link was the gear

teeth. Here you see a stock gear stack on the right...compared with

the custom gears we’re running shown on the left. If you look

closely, you’ll see the teeth on many gears are a LOT thicker. BTW,

this was a very expensive -- and difficult -- conversion.

We

had a problem with the teeth of the gears stripping. We're making

good power and on hard acceleration, the weak link was the gear

teeth. Here you see a stock gear stack on the right...compared with

the custom gears we’re running shown on the left. If you look

closely, you’ll see the teeth on many gears are a LOT thicker. BTW,

this was a very expensive -- and difficult -- conversion. Turning for a minute to the gearbox,

here’s a shot of the Quaife differentials mounted to a U.S. Spec (4.06) ring

gear. These differentials are great and really reduce the torque steer the car has.

Turning for a minute to the gearbox,

here’s a shot of the Quaife differentials mounted to a U.S. Spec (4.06) ring

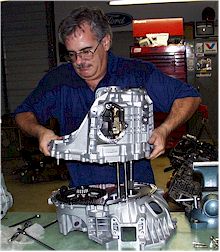

gear. These differentials are great and really reduce the torque steer the car has. Here’s Robert assembling the

transaxle. We are using a Euro spec gear set with the US final drive ratio.

This gives us a closer ratio transmission with better acceleration in the higher

gears. When combined with the Quaife differential, this would be really trick on the

street (but it is a pretty expensive proposition).

Here’s Robert assembling the

transaxle. We are using a Euro spec gear set with the US final drive ratio.

This gives us a closer ratio transmission with better acceleration in the higher

gears. When combined with the Quaife differential, this would be really trick on the

street (but it is a pretty expensive proposition).