SCCA Enterprises Engine Dyno |

||

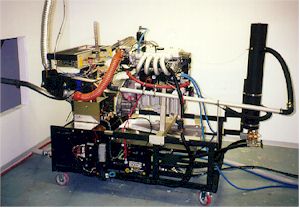

| SCCA Enterprises now has a new dyno, as seen in these

photographs. Our dynomometer for the Renault engines was totally destroyed in the infamous

fire of ’95 and we have, since then, been out of the engine rebuild and dyno

business.

The new piece is a SuperFlow 901,

(see http://www.Superflow.com/) with

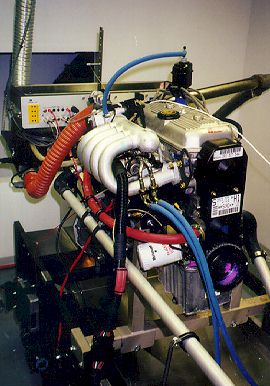

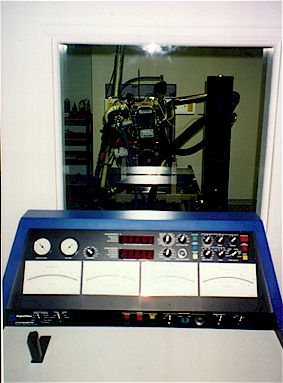

computer and incorporates their WinDyn software Extensive sealing was used at every joint, to provide best sound insulation. Even the electrical boxes were sealed to eliminate any possible sound leaks. An oversize fan draws air through the room, to pull out unwanted fumes. The air source for the engine is outside the room (note the vertical tube from the airbox) and helps provide a more stable source of intake air. The dyno stand utilizes the Roush wiring harness, The clearancing of the inside of the bellhousing to allow the use of the drive plate is a bit of a long story... to put it in a nutshell... it took several hours. Such is the way of doing a prototype dyno. We wanted to use the direct-drive feature of the SuperFlow design, but this was more than I had bargained for.

In order to best test the engine itself, Here’s to Better Racing Through Technology. |

||

| Dave

Liddle, Engine Department Manager/Compliance Director SCCA Enterprises, Inc. |

||

| Rev. 3/25/98 | ||

| Feedback | ||

| I welcome your comments or ideas on this

information. Feel free to drop me a line via “Comments for the

Bro’s”. Barry |

||

|

||

for computer control and data gathering. The dyno is

housed in a room specially constructed for dyno operation. The room, per SuperFlow

recommendations, is built using an offset-stud design, to isolate inner walls from outer

walls. All walls are insulated; inner walls having double-layer drywall, including

the ceiling.

for computer control and data gathering. The dyno is

housed in a room specially constructed for dyno operation. The room, per SuperFlow

recommendations, is built using an offset-stud design, to isolate inner walls from outer

walls. All walls are insulated; inner walls having double-layer drywall, including

the ceiling. EEC module and

associated electrics. The bellhousing is the SRF 5-speed, courtesy of California CSR

WinSpec. The adapter from dyno plate to bellhousing is a custom-made part,

fabricated at Innovation Engineering. The direct drive is made possible via another

Innovation Engineering custom-made piece; a “drive plate” which bolts up to the

Ford flywheel.

EEC module and

associated electrics. The bellhousing is the SRF 5-speed, courtesy of California CSR

WinSpec. The adapter from dyno plate to bellhousing is a custom-made part,

fabricated at Innovation Engineering. The direct drive is made possible via another

Innovation Engineering custom-made piece; a “drive plate” which bolts up to the

Ford flywheel. only one intake

manifold and injection unit, one exhaust manifold, one coil pack and plug wires

combination is going to be used. This is the only way to isolate variables in

testing procedures. In this manner, the variables are minimized and HP matching is

best accomplished.

only one intake

manifold and injection unit, one exhaust manifold, one coil pack and plug wires

combination is going to be used. This is the only way to isolate variables in

testing procedures. In this manner, the variables are minimized and HP matching is

best accomplished.