Chassis Rotisserie |

|

| Background | |

| What

follows is a reprise of some data I published in 1998.

I thought I had lost the pictures but recently located a backup.

I found this rotisserie immensely useful when preparing the car each winter. I don’t have the fixtures anymore (they went with the car)...and I don’t have drawings...but it’s pretty self evident and you should be able to figure it out if you want to build one. |

|

| The Rotisserie | |

| Overview The chassis rotisserie is based on the $40 engine stands you can buy from many sources such as Harbor Freight or Northern Tools. This picture shows the SRF chassis mounted on the two stands and rotated about 30 degrees.

There are 2 basic things you need

to do to make a rotisserie like this: Adapters

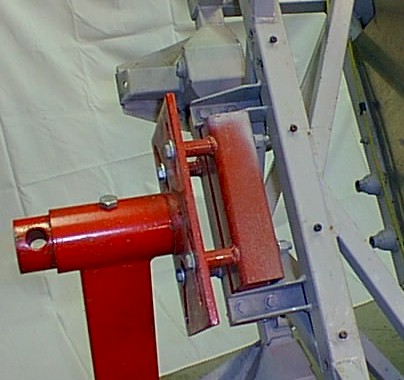

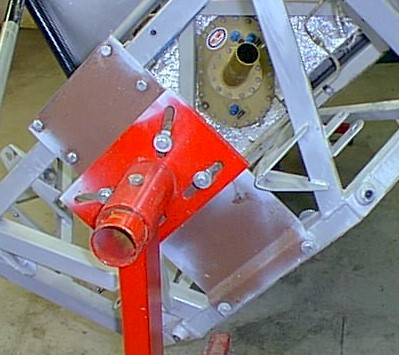

The adapter is a steel tube weldment. The tubes we used were 2 1/2" and 2" square with .125" wall. You could use almost anything you have here...as long as it’s relatively strong. Here is the rear adapter. You can see that we picked up the lower shock mounting holes and we created a U-channel to pick up the top cross frame tube.

The adapter is made from sheet steel with tube spacers welded to it as stand-offs. As I recall, we made this out of .100 or .125" sheet. Again, you could use what you have...as long as it’s strong.

Extensions

|

|

| Summary | |

| These

rotisseries were really a great deal when doing the winter rebuild. They held the car at standing height, they let you work on the bottom of

the car easily, and you could wheel the frame around the shop (or even

outside) for cleaning or welding.

Here’s a picture of yours truly enjoying an additional benefit of the rotisserie....extra support in remaining vertical.

|

|

Rev. 6/8/02 |

|